Services

Mold Process

Description of Each Development Step

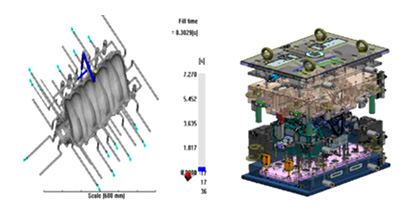

Step 01. Mold Flow & Mold Design

The first stage of mold development is mold flow & mold design stage. By analyzing the mold flow analysis data, we eliminate the potential problems in the product production phase in advance.

INTYCO pursues time and cost-saving caused by potential defects in the final product by meticulous analysis and checking in the mold flow & mold design stage.

Step 02. CAM Tooling

Once the analysis step is completed, the data created using the CAM program is input into the numerical control machine (NC, CNC, Milling, etc.) and then machining begins.

INTYCO uses an optimized CAM program to improve the quality of the mold and is applying a system that can satisfy with the product release schedule and quality.

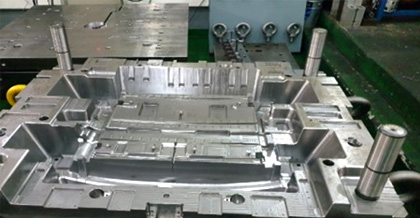

Step 03. Manufacture & Tool Trial

All processes can be processed with the combination of precision processing machines and skilled workers, and a system that demonstrates the highest efficiency is applied for each process with standardization.

Performing cooling leak testing, mold exterior inspection, and automatic testing to ensure there is no setback for the production schedules.

Step 04. Review

Manufactured molds are reconfirmed about potential defects in quality, design, and reliability, and this is systematized to apply immediately.

INTYCO's engineers meticulously inspect each one to prevent future defects, and the molds developed by INTYCO boast the highest quality.

Step 05. Measuring

This stage is to determine whether all the development has been completed by measuring the quality of the final product with a 3D measuring machine or CMM etc.

Products inspected by INTYCO are secondarily measured by the customer to complete the process.

Step 06. Product Released

It can be the truly finished product once the quantity requested from the customer is accurately and safely delivered.

INTYCO accurately figures out the number of products, confirms the safe packaging, and delivers them to domestic and international customers.